JH PCBA is a trusted one-stop automotive electronics bare PCB and PCB assembly manufacturer.

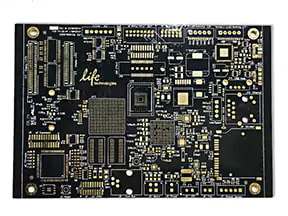

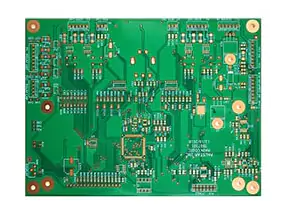

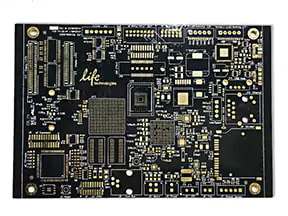

Automotive PCB

Automotive PCBs are the circuit boards used in automotive electronics from engine controls, anti-lock brake systems, and GPS, to rearview cameras and front lights. Safety and Reliability is the most important consideration for automotive PCB design and manufacturing.

Automotive PCBs have very strict quality standards and have many quality test items. And the whole processes including supply chain management, production process, quality test etc must be traceable. From the first process to the end, the entire manufacturing process of every automotive PCB board is recorded in a “PPAP level 3 required” report, including design documents records, material used, engineering change and communication, manufacturing process flow, operators, process control plan, quality control details, kinds of test reports etc.

Partners

Product Center

Automotive PCB

-

Car Audio PCB

-

GPS Navigation PCB

Security PCB

Industrial PCB

Power PCB

Medical PCB

Communication PCB

Quick-turn PCB Manufacturing Service Expert

Just prptype PCB cain be accelerated in JH PCBA?

No,small&Medium size PCB order can be too!

For exmple:8/10L,FR4 TG170,1.6mm, onemore core press-fit holes

IPC Class 3,ENIG2u”,outer layers 2oz inner layers all 1oz

- ·totally 9m2, fastest 3 days

- ·20-30m2, fastest 5 days

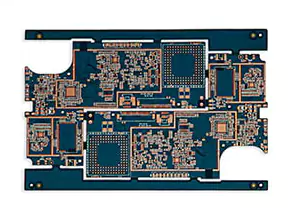

Quick Turn HDI PCB Manufacturer

HDI can’t expedited? No, JH PCBA can expedite too!

10L,2-step HDI PCB,10 m2, fastest 10 days 6L,1 step HDI PCB,prototype,fastest 48h 8L,any layer connection HDI PCB, prototype, fastest 6 days

- For new customers to try our quick manufacturing service Free expedite fee or 50% deduction!

High-Speed and High-Precision PCBA Production Lines

Make sure 100% original and new components,third-party test reports can be provided

Free BOM quotation,quote back in 24h

Good at"hard-to-find-"or obsolescent compoenents searching worldwide

Good at components alternatives solutions to lower whole cost

factory1

factory2

factory3

factory4

factory5

factory6

factory7

factory8

factory9

factory10

factory11

factory12

Quality Control

Pass Rate

Pass Rate≥99.8%

Quality Complaint Rate

Quality Complaint Rate≤0.2%

Rapid Prototyping Delivery Schedule 1

| Layers | 2 Layers | 4 Layers | 6 Layers/8 Lyaers | 10 Layers |

| PCB Order Quality (m2) | <1m2 | <1m2 | <1m2 | <1m2 |

| 1-5 m2 | 1-5 m2 | 1-5 m2 | 1-5 m2 | |

| >5 m2 | >5 m2 | >5 m2 | >5 m2 | |

| Build Time (Days) | 5 days | 5 days | 5 days | 5 days |

| 7 days | 7 days | 7 days | 7 days | |

| 8 days | 8 days | 8 days | 8 days | |

| Extra Urgent (Hours) | 24 Hours | 48 Hours | 72 Hours | 96 Hours |

Rapid Prototyping Delivery Schedule 2

| Layers | 2 Layers | 4 Layers | 6 Layers/8 Lyaers | 10 Layers |

| PCB Order Quality (m2) | <1m2 | <1m2 | <1m2 | <1m2 |

| 1-5 m2 | 1-5 m2 | 1-5 m2 | 1-5 m2 | |

| >5 m2 | >5 m2 | >5 m2 | >5 m2 | |

| Build Time (Days) | 5 days | 5 days | 5 days | 5 days |

| 7 days | 7 days | 7 days | 7 days | |

| 8 days | 8 days | 8 days | 8 days | |

| Extra Urgent (Hours) | 24 Hours | 48 Hours | 72 Hours | 96 Hours |

Our Team

Just like the PCB business, our PCBA services also specialise in prototyping and small-volume production, making PCBWay the one-stop destination for board fabrication and assembly. This arrangement makes your R&D work easy and time-saving.

What is Automotive PCB?

Automotive PCBs are the circuit boards used in automotive electronics from engine controls, anti-lock brake systems, and GPS, to rearview cameras and front lights. Safety and Reliability is the most important consideration for automotive PCB design and manufacturing. As more and more electric cars and hybrid electric vehicles drive on roads, the demand for reliable automotive PCBs rises. Automotive PCBs from JH PCBA are specially manufactured and assembled to support every system and application for vehicles. Automotive PCBs have very strict quality standards and have many quality test items. And the whole processes including supply chain management, production process, quality test etc must be traceable. From the first process to the end, the entire manufacturing process of every automotive PCB board is recorded in a "PPAP level 3 required" report, including design documents records, material used, engineering change and communication, manufacturing process flow, operators, process control plan, quality control details, kinds of test reports etc. The "PPAP level 3 required" report and a COC report are delivered with the automotive PCBs to the buyer. Meanwhile, JH PCBA's intelligent management system records all information for traceability. The one-stop automotive PCB manufacturer JH PCBA, an ISO 9001, ISO14001, IATF 16949 certified company, provides one-on-one engineering support and custom manufacturing solutions tailored to your needs.

Which parts of the car require PCBs?

Types of Automotive PCBs

Rigid PCBs: ·FR-42, FR-44, FR-46 ·CEM-I, CEM-III ·Polyimide ·Rogers Flexible PCBs:·Polyimide, ·Kapton Rigid-Flex PCBs HDI PCBs Metal Core PCBs Ceramic Substrate PCBs Heavy Copper PCBs

Key Automotive PCB Standards

The automotive pcb manufacturers follow these key automotive pcb standards in manufacturing: AEC-Q100/AEC-Q101/AEC-Q102/AEC-Q103/AEC-Q104/AEC-Q200/IPC-6012DA/IATF 16949 JH PCBA has been providing IPC Class 2/3 PCB manufacturing and assembly since 2009. The automotive industry components that JH PCBA sources are from the most reliable suppliers and traceable. You can check our automotive PCBA certifications, including ISO 9001:2015, ISO14001:2015, IATF 16949:2016

Major challenges of automotive electronics for PCB manufacturers ?

1.Harsh Environmental Conditions: Automotive PCBs must operate reliably under extreme conditions, including wide temperature ranges, humidity, vibrations, and exposure to dust, dirt, and chemicals. Designing for these conditions can be challenging. For working temperature range: The temperature range of the engine compartment is between -40°C and 150°C. Therefore, automotive chips and circuit boards need to meet this wide temperature range, while consumer chips only need to meet 0°C~70°C working environment. More, vehicles are sold worldwide, and different regions often have different environmental characteristics of temperatures and humidity. Therefore, automotive PCBs must be able to adapt to different environments, although some manufacturers make PCBs for specific environments. 2. Vibration and Shock Resistance: ·Vibration from engine and road noises. ·Shock from bumps and unequal road surfaces. 3.Resist the threat of dirty, humid and various chemical corrosion: ·certain anti-corrosion ability: PCB boards have good resist to the threat of various chemical corrosion such as corrosive acid, organic solvent, salt water, etc. ·Resist to the accumulation of dirt during years of operation is critical. In order to help PCB and PCBA boards have the good resist to threat of dirty and various chemical corrosion, JH PCBA normally brush solder mask oil onto PCB board surface and spray conformal coating to PCBA boards to protect bare boards and exposed components joints, so that we can use boards even in dusty and humid environments and prevent oxidation and chemical corrosion. High Reliability, High-Security and Long Product Life Cycle ·the design life of automotive is generally around 15-20 years or 200,000 kilometers ·the expected operating life as long as 10+ years ·Acceptable Failure Rates: 0 (Zero Failure) High-Security Requests In addition to providing comfort, the automotive must ensure the safety of the entire vehicle system and even 0 zero defects. In addition, with the popularization of electric vehicles, the importance of information security is becoming more and more prominent. As a real-time online device, The communication between it and the network, including the communication with the in-vehicle network, requires data encryption. Below are picture showing compare between Automotive, Industrial, Consumer 3 different level quality standard from more aspects to help understand the stringency of automotive PCBA quality request. So automotive PCBA level quality standards is all-around and multidimensional, only control in this strict way can make sure finished cars, combined with hundreds of ECU and tens of thousands of different kinds electronic components, to realize long life-span usage and high reliability. From the first process to the end, automotive PCBs whole manufacturing process must be traceable Automotive PCBs whole process must be traceable. From the first process to the end, the entire manufacturing process of every automotive PCB board is recorded in a "PPAP level 3 required" report, including material used, manufacturing process flow, operators, machine specifications, quality control details, test reports etc. The "PPAP level 3 required" report and a COC report are delivered with the automotive PCBs to the buyer. Meanwhile, JH PCBA's intelligent MES management system records all information for traceability. And we provide free DFM, DFT, and DFX for your automotive PCB and PCBA project. Give us your BOM, Gerber, and pick-and-place file, we will quote you back in 24h, we can serve you one-stop PCB need from PCB design, PCB production, PCBA production, components sourcing worldwide till finished product assembly.

Our expertise is here to serve you

How long have you been making PCB&PCBA?

Pcbamake has been making PCBs for more than 26 years.We built our assembly plant and begin assembly business in 1996.

How do l get a quick quote for PCB or PCB assembly?

How do l get a quick quote for PCB or PCB assembly?

Do you cater SiT prototype boards?

Do you cater SiT prototype boards?

What files and documents do you request for my PCBA orders?

What files and documents do you request for my PCBA orders?